It's Your Money!

This page is filled with examples of design flaws and shoddy workmanship. However "funny" they may seem they are real and real people spent real money on them thinking they were getting a quality bagpipe. I ve done my best to not reveal the makers. Suffice to say that they re all still in business.

This page is filled with examples of design flaws and shoddy workmanship. However "funny" they may seem they are real and real people spent real money on them thinking they were getting a quality bagpipe. I ve done my best to not reveal the makers. Suffice to say that they re all still in business.

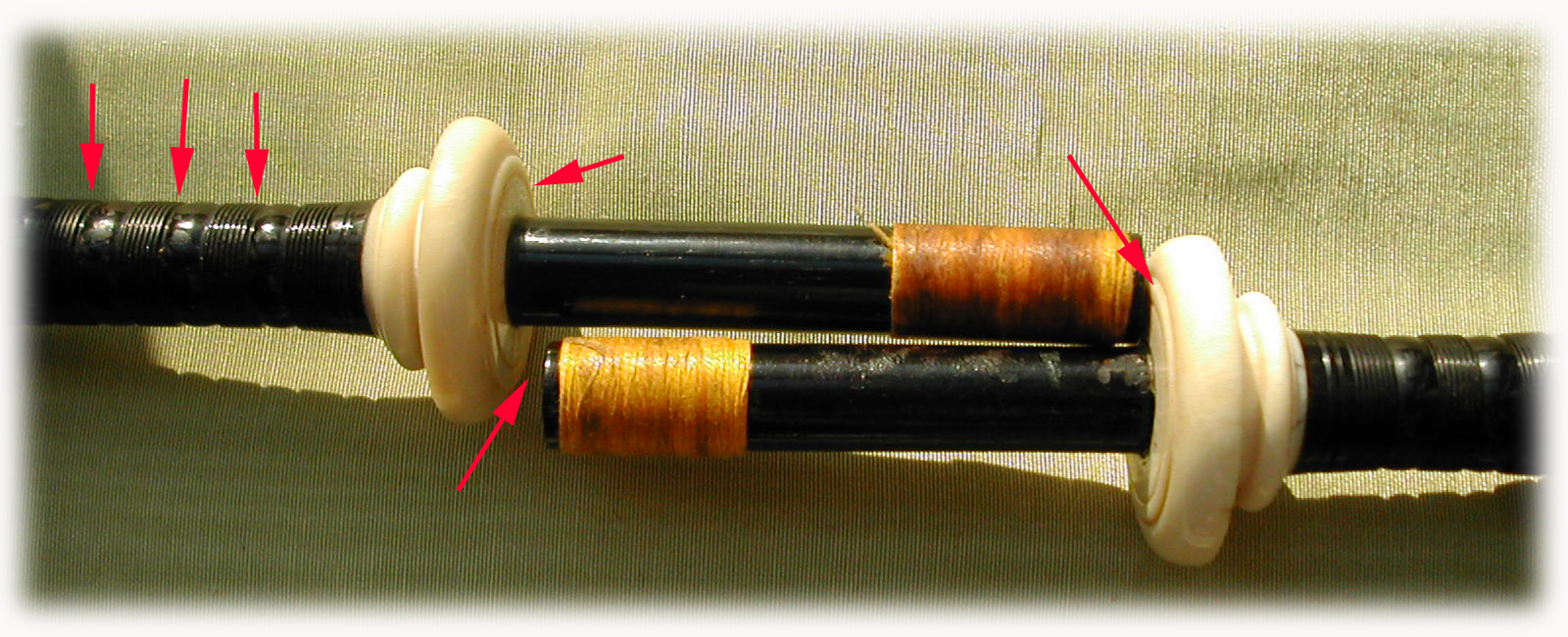

Here are two "matching" tenor drones. The bagpipe was bought new directly from the maker. Very poor job, to be certain. Compare all the pieces of your bagpipe carefully before you put your money down. Old or new, everything should match up. This means stocks, beading and combing, profiles, bored, etc.

This is a real shame. The internal bore left little support for the bell. It didn't take much for the bell to come away from the neck. This was probably a combination of poor quality wood and a bad inside boring job. However look at the finish! Very shiny!

The tale of two tenor drones! Look at the projecting mounts. Obviously one doesn't belong on the bottom. I suspect that the mount on the far right is the top mount for the tenor bottom. The maker looks to have compensated by turning the wood to match the mount.

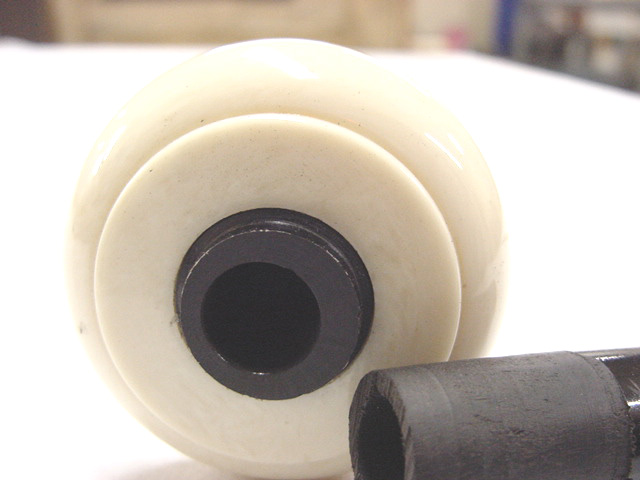

Quite the off-centre bore!

Two tenor pins....that don't quite match up! I wonder what that sounds like?

Here's a dicey situation. Tuning pin "repair" that was not-so-professional. The pin should have been threaded and the bore should have been tapped to receive the pin properly. Done correctly it is a repair that will last a lifetime. Done poorly and you'll probably have to replace the piece sooner or later.

New from the maker, but the tuning pin wasn't finished. The maker made good on this however you still have to wonder how it went out like that.

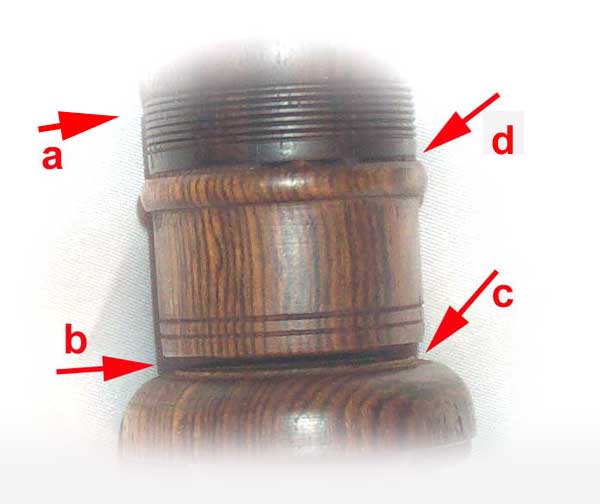

Here's a little trick. If you turn a piece down too small, just build it back up using wood dust and glue!

And now you know why we like mounts threaded and fitted into place. This is just crap!

I hate sloppy re-silvering. Made new, the bagpipe would have been made to fit the silver. It's quite another matter going in the other direction. The picture blow shows what they did to get the ferrule to fit the tenor top.

and the picture below shows an ill-fitted cap. Now was it really worth mucking up a 100 year old cocuswood Henderson for a little bling? You can see the cap is too big for the bell. Also, look closely at the combing. It's been cut into to accommodate the depth of the cap!

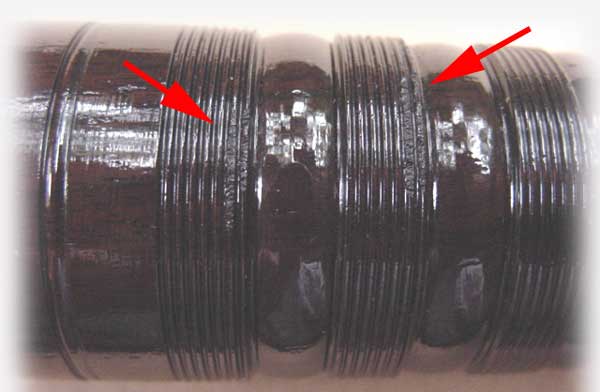

This is what maker's call "chatter" where the cutting tool is hopping and leaves an uneven surface.

The cap isn't fitted properly, leaving a visible gap.

You have to wonder about this. Can't quite decide how many teeth per comb.

Torn Combing. Not even the thick syrupy finish could hide that!

Here's another example of ill-fitted pieces. The ferrule leaves a gap, as does the top section onto the bottom section.

This is a story! I was conducting a workshop when a piper came to me in desparation. "I just can't keep them going. I'm ready to quit!" Through process of elimination, we pinpointed the problem. A tenor stock (shown to the left) had a gaping hole! This was original to the piece. I was a hero on that day!

Worm holes! This was discovered during refurbishing of these pipes. They have been filled by the maker and hidden with the top coat finish. You won't find this with the best makers.

Mistakes happen, but you wonder how sometimes.

Now none of this is intended to embarass anyone. Mistakes do happen and I haven't nearly represented all the mistakes I've encountered here on this page. I've encountered misaligned bores, bass bushings in tenor drones, glue smears under the clear overcoat, and just about everything you could imagine. None of this is to suggest anything other than you need to know what you're looking for.

Manufacturing Flaws!