This method is the easiest, fastest, and best way of tying in a hide pipe bag. There are no knots to rub and wear holes in the hide or to loosen and fall out. You are using more of your overall body strength rather than arm strength to tighten the wrap. Using this method, it is possible to expertly tie-in a pipe bag in about twenty minutes.

Why would anyone want to tie a set of stocks into a bag. Interesting question. Over the years synthetic bags have introduced an alternative to the tradition of tying stocks to a bag. There are rubber grommets which are fixed in place and glued to the bag. Stocks are inserted up through the bag and secured with tape or hose clamps. This is an outstanding innovation and serves a wide segment of the market quite well. However, most top-level competing pipers will argue that rubber grommets rob the drones of resonance and life.

The Ross "Suede" grommeted bag is pictured to the left. This is just one of several synthetic, hybrid, and hide bags that are fitted with rubber grommets.

The picture to the left shows a hide (sheepskin in this case) bag without grommets, which would require traditional tying of stocks. This particular bag has the holes pre-cut to make the job a bit less nerve-wracking. It also has a zipper glued to to the bag to allow access for moisture management. Modern glues and materials have allowed for improvements to this essential component of the GHB as in no time before.

First of all, we should talk about the size of the bag. Generally speaking a medium size bag will suit those over 5' 8". In my experience, there are few pipers who are comfortable with "large" bags however I will stop short of discounting large bags altogether. Many pipers prefer small bags or "extended" small bags. Selection of the pipe bag is very important to the comfort of the piper. It is equally important in how the bagpipe will perform. Look for well-made bags, with even stitching and well finished details. As with any manufactured product, quality of craftsmanship shows and is a good indication that the product will perform up to your expectations. Pipe bags generally come in small, medium, and large sizes. Bags can be custom built if required. All pipe bags will stretch, some slightly, some dramatically, so test the sizes on a bag that has been played for a period of time to determine the size most comfortable for you.

All stocks should be properly secured to your new pipe bag. Some bags, like Ross bags, are manufactured with pre-determined stock holes. Securing your stocks to these bags may involve hose-clamps, black electrical tape, and other items not used with leather bags. It is best to follow the manufacturer’s instructions or to consult with a knowledgeable associate who is experienced in these matters.

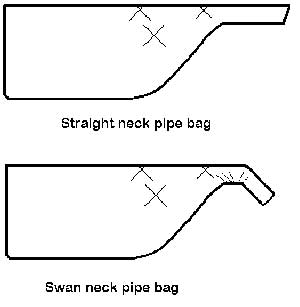

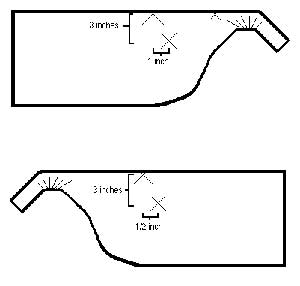

Hide bags must be measured, cut, and precisely tied in to ensure performance and comfort. The middle drone stock is positioned in the center, top of the bag, usually determined by folding the bag front to back and marking the top fold. The other stocks are positioned as in the pictures herein. A rule of thumb is to position the bass stock 3" from the top of the bag and 1" forward of center. The outside tenor stock is positioned (on the opposite side of course) 3" from the top of the bag and 1/2" aft of center. The blowpipe stock is positioned 1/2" from the top of the bag on the right side of the bag, halfway between the middle of the bag and the neck end.

Hide bags must be measured, cut, and precisely tied in to ensure performance and comfort. The middle drone stock is positioned in the center, top of the bag, usually determined by folding the bag front to back and marking the top fold. The other stocks are positioned as in the pictures herein. A rule of thumb is to position the bass stock 3" from the top of the bag and 1" forward of center. The outside tenor stock is positioned (on the opposite side of course) 3" from the top of the bag and 1/2" aft of center. The blowpipe stock is positioned 1/2" from the top of the bag on the right side of the bag, halfway between the middle of the bag and the neck end.

There are those that recommend reversing the angle of the drones, especially for young pipers. The reverse angle positions the tenor drones away from the piper's arm, making it easier to reach the chanter with your left hand. This is an excellent concept. I have not played or tied-in a bag as such and would recommend that you seek someone who has, prior to trying it yourself. If possible, play a set tied in as such to judge the feel and comfort prior to making any commitment. Ask your pipe maker or Pipe Major for his recommendation.

When the bag has been marked, cut diagonally across the center position with a sharp knife or cut a circle slightly smaller than the circumference of the top of stock to be tied in. Be sure that your cuts do not exceed the circumference of the top of the drone stock to be inserted. Another method is to insert the drone, position the top of the drone against the position mark, and cut until the bag can be forced down over the top of the stock.

Once the cuts have been made, insert the stock into the open "mouth" of the bag (at the neck) and push the stock up through the cut opening. The leather will stretch tightly around the stock. The stock is tied at a point below the cuts where the indentation occurs in the stock.

When the bag has been marked, cut diagonally across the center position with a sharp knife or cut a circle slightly smaller than the circumference of the top of stock to be tied in. Be sure that your cuts do not exceed the circumference of the top of the drone stock to be inserted. Another method is to insert the drone, position the top of the drone against the position mark, and cut until the bag can be forced down over the top of the stock.

Once the cuts have been made, insert the stock into the open "mouth" of the bag (at the neck) and push the stock up through the cut opening. The leather will stretch tightly around the stock. The stock is tied at a point below the cuts where the indentation occurs in the stock.

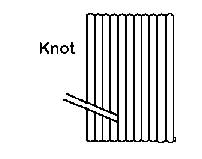

Great care must be used to tie the stock to the bag. The twine must be quite strong. If the pipe bag supplier does not supply twine, a substitute may be made with hemp. Using cobblers wax, resin at least ten strands of hemp, each one being perhaps ten or fifteen yards in length. Twist the strands together making a single rope of the strands. A piece about twenty inches in length should be cut off, set aside, and used a herein described. The remainder should be wound onto a flat stick with smooth edges. I use a piece of 1 x 4 maple with the edges rounded off.

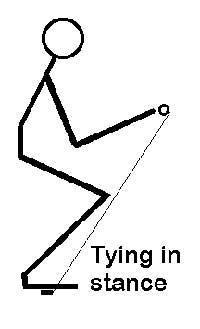

A length about three or four feet should be peeled off the stick. The stick should then be placed on the floor for you to stand on. Start with a half hitch and insert the stock. Pull the stock and twine up from the floor, making the hitch snug around the stock. Now twist the stock, wrapping the twine around the stock as you twist, keeping pressure on the twine by pulling upwards or straightening up.

A length about three or four feet should be peeled off the stick. The stick should then be placed on the floor for you to stand on. Start with a half hitch and insert the stock. Pull the stock and twine up from the floor, making the hitch snug around the stock. Now twist the stock, wrapping the twine around the stock as you twist, keeping pressure on the twine by pulling upwards or straightening up.

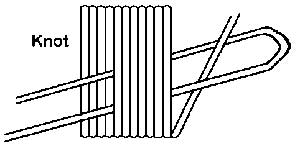

After one or two circuits of the stock, double the twenty inch length and place it directly under where the twine is meeting the stock. The loop should be extended only about one inch. Continue to twist the stock and wrap the twine several times over this loop. Holding the twine against the stock with your thumb cut the twine leaving enough to pass through the loop by about three inches. Grasping the loose ends of the twenty inch length, pull the loop and three-inch end under the several wraps of twine. The stock should now be securely tied into the bag now.

The chanter stock is the most difficult stock to make airtight, as you are tying over the leather welt. Proceed as described above. Place small "packing pieces" on either side of the welt, to assist in making the seal airtight. These packing pieces are usually just small strips of leather, rolled into a barrel about one inch long, positioned under the first strand of tying-in twine.

The chanter stock is the most difficult stock to make airtight, as you are tying over the leather welt. Proceed as described above. Place small "packing pieces" on either side of the welt, to assist in making the seal airtight. These packing pieces are usually just small strips of leather, rolled into a barrel about one inch long, positioned under the first strand of tying-in twine.

Tying in a Hide Bag